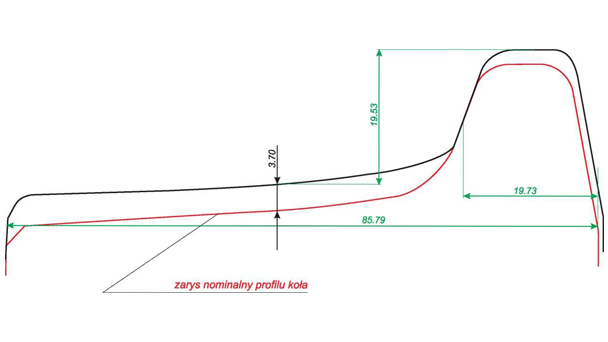

The wheel profile optimisation system is based on the software analysing data related to the dimensions of wheels obtained from e.g. Laser system for wheelset measurements.

The system offer the following functions:

- Selection of optimal profile and Wheel tread diameters for all wheels of a vehicle before machining on an Underfloor Wheel Lathe. Thanks to such an analyse during the cutting process a minimum layer of material necessary to restore the correct profile is removed from the wheels. This allows to extend the wheelset life time and to significantly shorten the machining time of each wheelset and the entire vehicle.

- Creation of any new wheel profile according to the user’s needs.

- Wheelset data collection and storage on local data base and two-way communication with User’s data base.

Other products from this category

ABOVEFLOOR WHEEL LATHES (4)

UNDERFLOOR WHEEL LATHE (4)

IT SYSTEMS (4)

MEASURING SYSTEMS (4)

DIAGNOSTIC SYSTEMS (4)

SHUNTING EQUIPMENT (4)

WHEEL BORING MACHINE (4)

AXLE LATHE (4)

MILLING MACHINE FOR BOGIE FRAMES (4)

EQUIPMENT FOR TECHNOLOGICAL LINES (4)